drying application!! hot air boiler, coal fired hot air boiler 0.6 Gcal--4.8 GKcal

- Products Details

Quick Details

-

Brand Name: TAIGUO

Model Number: WRFL

Place of Origin: Henan, China (Mainland)

Packaging & Delivery

- Packaging Details: Main-body naked, auxiliaries packed with plywood box or plastic film.

- Delivery Detail: Average 20 working days after the down payment

Specifications

Product Description

- WRFL series is a new type of high efficiency hot blast stove, which is mainly used in large and medium heat supply, especially suitable for spray drying, granulation, air drying, tower drying, tunnel drying, rotary drum drying, and so on. Widely used in chemical industry, building materials, metallurgy, medicine, food processing, agricultural production and other industries.

- The entire processes of hot blast stove realise automatic fuel feeding, automatic burning, automatic ash removing, automatic heat exchanging. Markedly can save user's labour intensity and labour cost.

- The output of the hot blast stove is heated by heat exchanger, and the constant temperature and clean air is produced. According to the different requirements of dry material, the output temperature of hot air can be adjusted between 0 and 550.

- The hot blast stove is made of combustion furnace and heat exchanger. The split type structure is used to control the temperature of the high temperature flue gas into the chamber, and to extend the service life of the heat exchanger.

- When fuel is burning in the combustion furnace, it will generate high temperature gas. High temperature flue gas enters the heat exchange chamber, and exchange the heat with the heat exchanger. The flue gas is discharged through the dust collector, finally sent to the chimney by the air blower.

- The clean air is fed into the heat exchanger via heat exchanger blower, and the heat transfer process is completed by the tube of the heat exchangers at the low temperature section and low temperature section; finally output from the hot air exit of the heat exchanger.

The Catalogue

Note: If you cannot find suitable model in above catalogue, please contact us!

|

Model |

ZLRFR-60 |

WRFH-120 |

WRFL-120 |

WRFL-240 |

WRFL-360 |

|

Heating capacity |

600,000 Kcal/hr |

1,200,000 Kcal/hr |

1,200,000 Kcal/hr |

2,400,000 Kcal/hr |

3,600,000 Kcal/hr |

|

Heating capacity |

700KW/hr |

1,400 KW/hr |

1,400 KW/hr |

2,800 KW/hr |

4, 200 KW/hr |

|

Hot air temperature |

50-500℃ |

||||

|

Fuel |

Coal, waste wood, biomass fuel |

||||

|

Combustion type |

Fixed chain grate |

Traveling chain grate |

|||

|

Operation type |

Manual fuel feeding/deslagging |

Automatic fuel feeding/deslagging |

|||

|

Products Structure |

Vertical type |

Horizontal type |

|||

|

Mainbody dimension |

Φ2*H4.5m |

5.29*2.10*3.4m |

5.95*2.10*3.4m |

6.55*2.10*4.20m |

7.79*2.60*3.93m |

|

Mainbody Weight |

6274Kg |

14400Kg |

15650Kg |

24995Kg |

34850Kg |

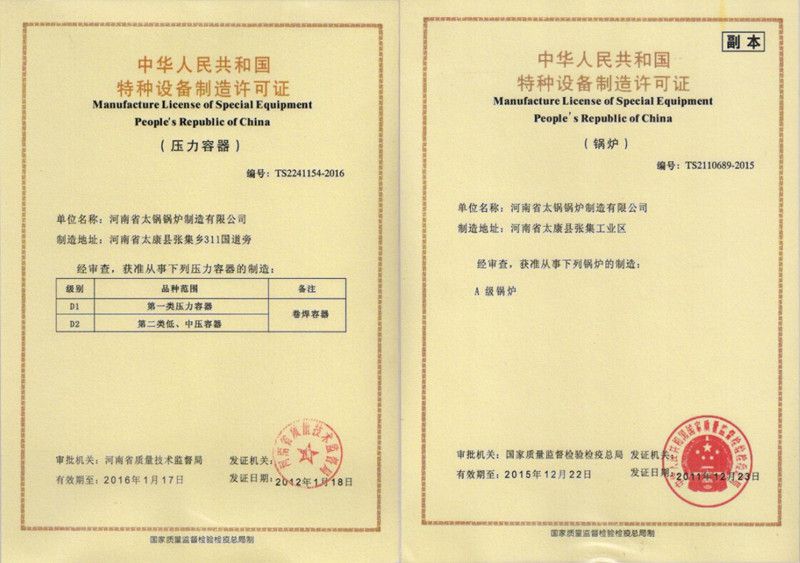

Quality Control

- Strength calculation report with applied materials information;

- Hydraulic test report: ensure the standard working pressure and safety;

- 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

- 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler;

- Third-party inspection report: by Zhoukou Institute of Special Equipment Inspection & Technical Research.

Customers Visiting

- The customers comes from different counties for the boiler business negotiation.

- We have many successful cases in Thailand, Russia, Pakistan, Philippines; Kenya, Algeria, Iran, Saudi Arabia; Nicaragua, Colombia, etc.

Packaging & Shipping

- Accoring to the requirements of customers, our company can accept CIF, FOB, EXW;

- We have own delivery team and ocean shipping cooperative partner for handeling the inland transportation & ocean carriage;

Our Services

- Free change: 24 months for the mainbody, 12months for components;

- Our company sends one professional engineer for guiding the installation, opertation and maintenance.

Company Information

- TAIGUO founded since 1976 as the Chinese government appointed Grade A Quality Leading Boiler Manufacturer in China; Company team: Total about 277 staffs. Chairman 1, CEO 1, Senior Engineer 5, Intermediate Engineers 15, Front-line Staffs 150, Sales 75, After-sale service team 30 (Quality tracking 5, Delivery 5, Installation 20).

- Our study team has close relation with the most Chinese famous study institutes; such as Shanghai Jiao Tong University, Northwestern Polytechnical University, Beijing University of Technology. Besides, introduced advanced manufacturing devices and quality detecting equipment to ensure the products quality; such as Automatic welding machine, Automatic bending machine, Automatic cutting machine, Tensile testing machine, X ray flaw detection device, Water pressure test machine, etc. Standard workshop ensure the finished products keeping good quality and nice looking.

- Third party inspection report to reconfirm the final quality: by Zhoukou Institute of Special Equipment Inspection & Technical Research (China official). Factory area 40000 square meter, total building area 80000 square meters.

The Details Image

Scale: 101 - 200 People

Country/Region: China (Mainland)/Asia

Established:

USD 7000-26000 / Set 1 Unit (Min.Order)

USD 5000-80000 / Set 1 Unit (Min.Order)

USD 5000-80000 / Set 1 Unit (Min.Order)